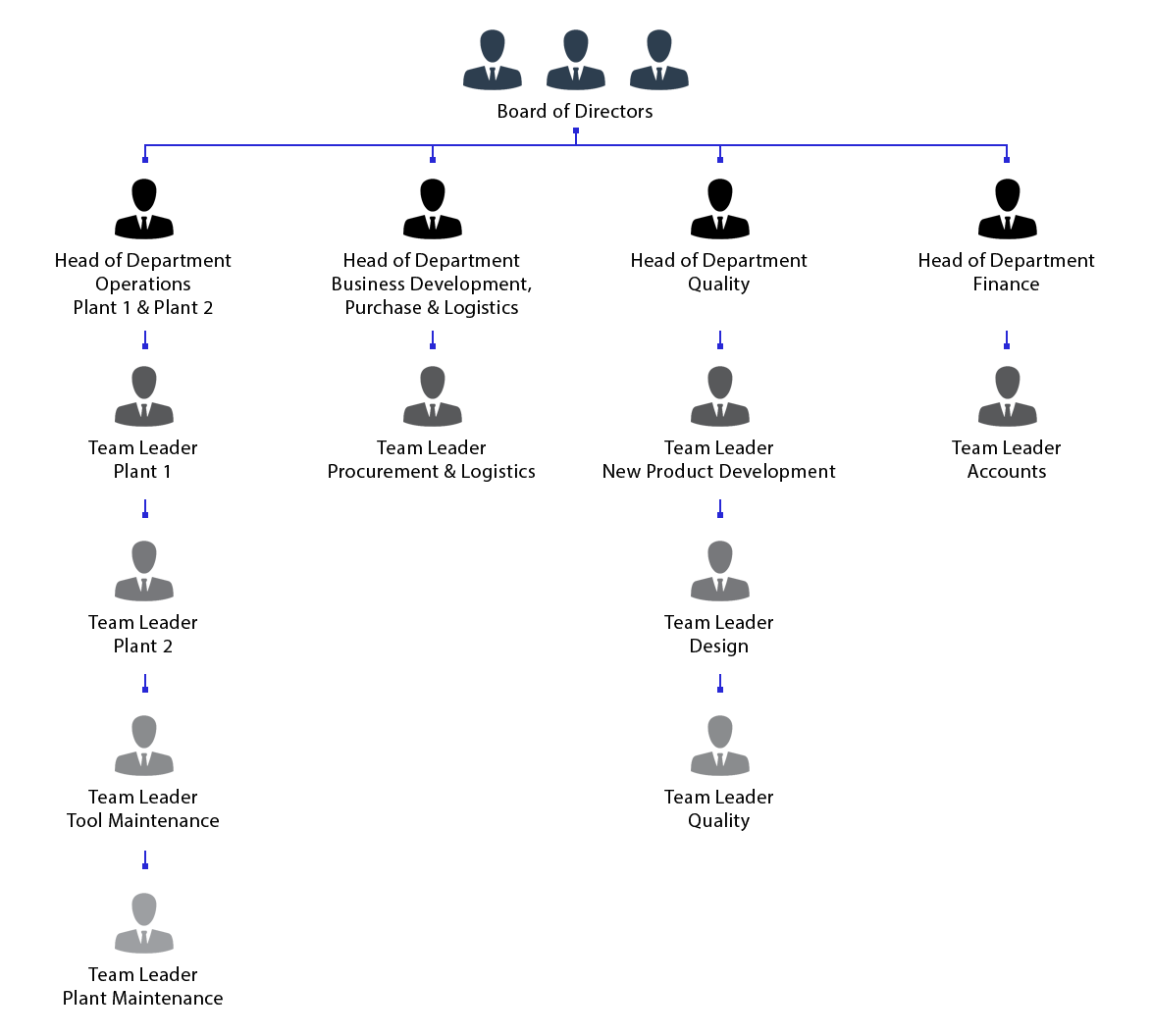

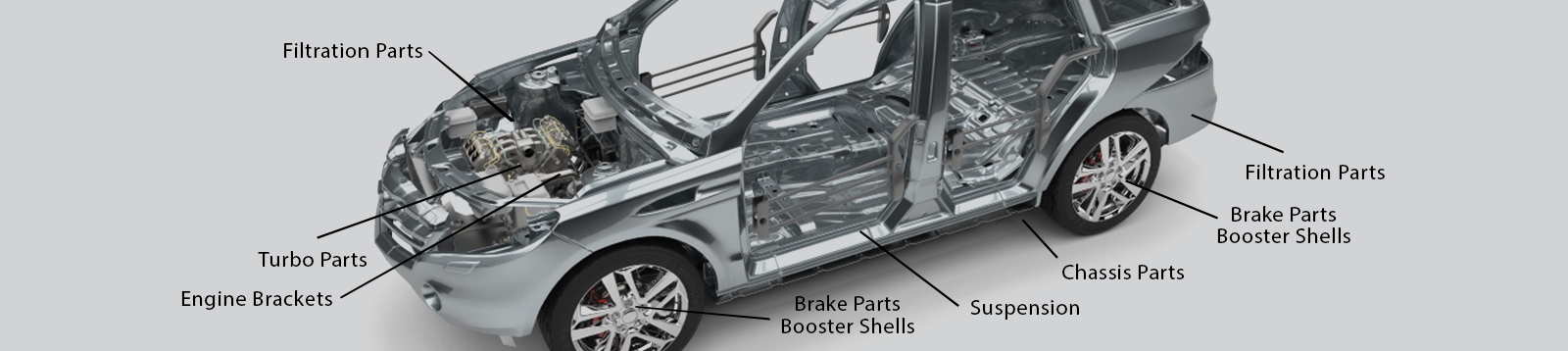

Dyna-K Automotive Stampings Private Limited was founded in December 1985, to cater to the requirements of precision stampings & pressed components for the automotive industry. Over the years, Dyna-K Automotive Stampings Private Limited capitalized on its tool design capability to cater to added automotive requirements and safety requirements of stampings for Brake components, Welded Assemblies, Engine Parts, Turbo Charger parts etc.

Since commencing operation, Dyna- K has achieved many milestones and emerged as one of the preferred suppliers. Our partnership as a supplier commences from the early tool design stage to production and supply. With robust manufacturing driven by TQM , Lean practices and required investment in technology we have built strategic partnerships with Tier 1 and OEM Suppliers.

Dyna-K Automotive Stampings Private Limited is equipped with a stamping & assembly facility which is spread in 2 plants with an approx. 52,000 sq. ft. area of workshops in Pune MIDC Industrial Area. Coupled with in-house tool design & manufacturing, Dyna-K Automotive Stampings Private Limited is aTS 16949 Certified Quality Organisation and geared to meet and exceed its customer expectations.

-

1985

Founded J450 unite with a Capital Outlay of Rs.1M.

-

1986-1990

Developed Range of Critical Brake Stampings

-

1991

Initiated relationship with Maruti - Developed Critical Suspension

-

1993

J6 Plant Established

-

1997

Developed Range of Critical Turbocharger Stampings

-

1998

Developed Critical stampings for Brake Boosters

-

2001

Established QS-9000 Quality Systems

-

2003

Export of Turbocharger Stampings to US & UK.

-

2004

Initiated a Business relationship with Cummins Engine Business Unit

-

2005

Established TS-16949 Quality Systems

-

2006

Export of Turbocharger Stampings for passenger cars-European Market

-

2009

Developed range of stampings for Filter assemblies for European market

-

2010

Initiated relationship with VW - Developed Critical Chassis Parts

-

2011

Press Line Modernisation- 15 New Press added

-

2014

Acquisition of 280,000 Sq.M Industrial land for Expansion and Plant 3